Dress shirt fabrics come in various constructions such as

oxford, herringbone, twill, poplin, end-on-end, pinpoint, basket weave, ginham,

etc. Most of which are woven

fabrics. Shirt fabrics are also referenced as "shirtings".

Cotton is by

far the most common fabric for dress shirts, and most fabric names refer to a

particular method of weaving the shirting fabric. The numbers sometimes listed

with fabrics denote the thickness of the yarn from which the fabric is made;

higher numbers mean thinner yarn. The finer yarn results in a finer clothing

and typically higher prices.

Yarn is the generic term for a thin, long, continuous

strand of textile fiber before it is woven into cloth.

A yarn number tells you the diameter of the yarn used

in the fabric. Fabric has a lower yarn number because the yarn used to make the

shirt is wider. Thinner fabric has a higher number. Typically 80-100 signifies

high quality. Thread count is often referred to with a number like 50s, 80s,

100s, 120s, 140s 160s, etc. up to 200s.

Ply is a term used to describe the number of yarns

that are spun together in the shirt fabric. Two ply means that two different

yarns are twisted together before the shirting fabric is woven. Fabrics can

either be two-ply or single ply.

You might see a fabric’s construction described as something

like “100/2×100/2″. The way to read this is that it has 100s two-ply threads

running in both the warp and weft directions. Warp threads run vertically. Weft

yarns run horizontally.

Broadcloth—very similar to poplin–is a tightly woven

fabric with a very simple over-under weave and slight sheen, which makes it very

dressy. Broadcloths are great for guys looking for as little texture as

possible in their fabrics. They are generally a thinner, lighter

fabric.

Oxford vs. Pinpoint - The difference between the

fabrics is not in the weave, but in the thickness and weight of the yarns that

are used. Pinpoint generally has a higher thread count, and a lighter, finer

weave then Oxford Cloth. Thus, pinpoint dress shirts are preferable over oxford

cloth dress shirts in formal situations.

The construction of the cloth and yarn count is only part of

the shirt fabric puzzle. The fabric also must complete a proper finishing

process to be prepared for being cut and sewn into dress shirts. There are a

variety of processes that must occur before the cloth is considered “finished.”

These processes are referred to as the “finishing.” This process can include

dying, sizing, pre-shrinking, and sanforization (Sanforization is a process of

treatment used for cotton fabrics mainly and most textiles made from natural or

chemical fibres, patented by Sanford Lockwood Cluett) to name just a few common

ones. Some finishing techniques such as bleaching and dyeing are applied to

yarn before it is woven while others are applied to the grey cloth directly

after it is woven or knitted. Each of these processes has a direct effect not

only on the appearance of the cloth, but also on how it later

performs.

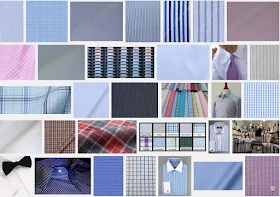

Dress Shirt

Weaves (Charles Tyrwhitt shirts)

If you are a fashion designer looking for factories to manufacturer your dress shirts in the shirting fabric construction of your choice, you can check the dress shirt factory section of our clothing factory area.

Learn more about fabrics from our fabric mill section.

Thank you for taking the time to read our fashion industry blog post. We hope that you have found this news to be informative. If you have comments or questions, please add your thoughts in the discussion area below.